With the rapid development of automated production, automated manufacturing solutions are becoming the core driving force of modern industry. From automobile manufacturing to electronic product production, from engineering machinery to medical device manufacturing, automation technology is gradually replacing traditional production models, bringing higher efficiency, lower costs and better products to enterprises.

Automated manufacturing solutions refer to the automation, intelligence and efficiency of the production process through advanced machinery, robots, computer control systems and artificial intelligence technologies. It covers the entire production process from raw material handling, processing, welding, assembly to quality inspection and packaging.

Automated manufacturing solutions refer to the automation, intelligence and efficiency of the production process through advanced machinery, robots, computer control systems and artificial intelligence technologies. It covers the entire production process from raw material handling, processing, welding, assembly to quality inspection and packaging.

Core components:

Industrial robots: used for tasks such as handling, welding, spraying, and assembly.

Automated equipment: such as CNC machine tools and automated assembly lines.

Sensors and the Internet of Things (IoT): real-time monitoring of production status and optimization of processes.

Artificial intelligence and machine learning: used for data analysis, predictive maintenance and process optimization.

Computer control systems: such as PLC (programmable logic controller) and SCADA (supervisory control and data acquisition system).

2. Advantages of automated manufacturing solutions

(1) Improve production efficiency

Automated equipment can work 24 hours a day, greatly improving production speed.

Reduce human operating errors and improve product consistency.

(2) Reduce production costs

Reduce dependence on manual labor and reduce labor costs.

Reduce raw material waste by optimizing resource utilization.

(3) Improve product quality

The automated system can accurately control production parameters to ensure high product quality.

Detect and correct problems in production in real time to reduce defective rates.

(4) Enhance flexibility

Automated production lines can be quickly adjusted to meet the production needs of different products.

Support customized production of small batches and multiple varieties.

(5) Improve the working environment

Free workers from dangerous, repetitive and heavy tasks and improve work safety.

Allow employees to participate more in technical management and innovation.

3. Application areas of automated manufacturing

Manufacturing automation solutions are widely used in many industries to improve production efficiency and welding quality. First, in the automotive manufacturing industry, automated welding robots are widely used in body welding, chassis assembly and other links to improve production speed and precision. Secondly, in shipbuilding, welding automation solutions are used for welding of hulls, cabins and other parts to ensure strength and sealing. The iron and steel metallurgical industry also uses automated welding technology to improve production line efficiency, especially in steel plate welding, pipeline connection and other operations. In the fields of electronic products, home appliance manufacturing and aerospace, automated welding solutions can accurately weld small parts to ensure product quality and stability. In addition, the application of automated welding solutions is also crucial in high-precision welding needs such as pipeline construction, pressure vessel manufacturing and energy fields (such as nuclear power and oil).

4. Challenges of automated manufacturing

High initial investment: The purchase cost of automated equipment and systems is high, which may be difficult for small and medium-sized enterprises to afford.

Technical complexity: Professional technicians are required for design, installation and maintenance.

Employment structure adjustment: Automation may replace some low-skilled positions, and employees need to be retrained.

Data security risks: Automated systems that are highly dependent on networks and data may face the risk of hacker attacks.

5. Conclusion

Automated manufacturing solutions are changing the landscape of the global manufacturing industry. Through automation technology, companies can not only improve their competitiveness, but also create greater value for society. In the future, with the continuous advancement of technology, automated manufacturing will become the core engine of the Industrial 4.0 era, driving mankind towards a more intelligent, efficient and sustainable future.

Automobile Body Production Line Welding Fixtures

Automobile Body Production Line Welding Fixtures  Automotive Body Welding Automated Manufacturing Solutions

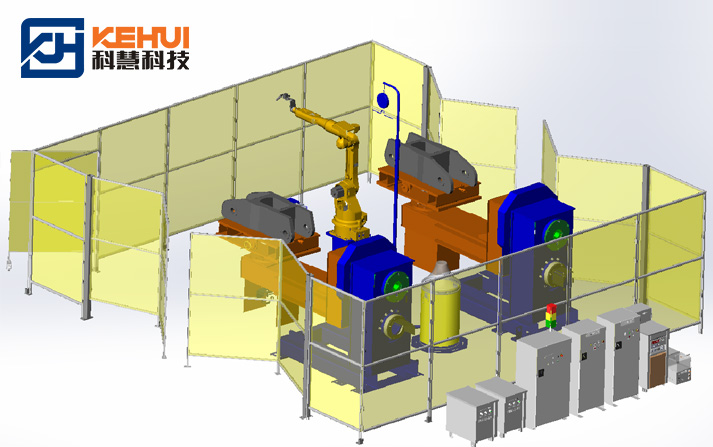

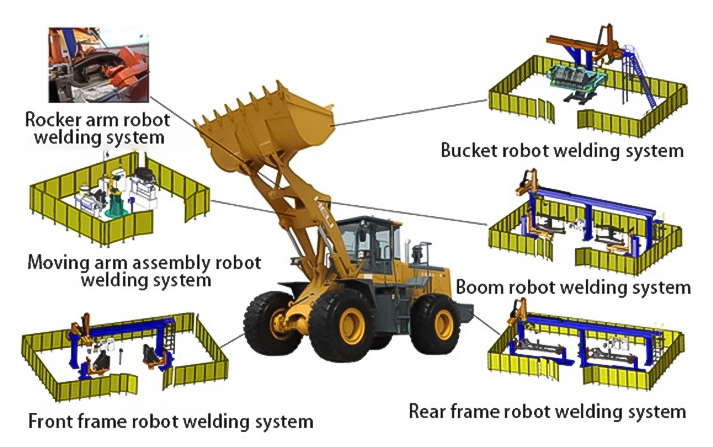

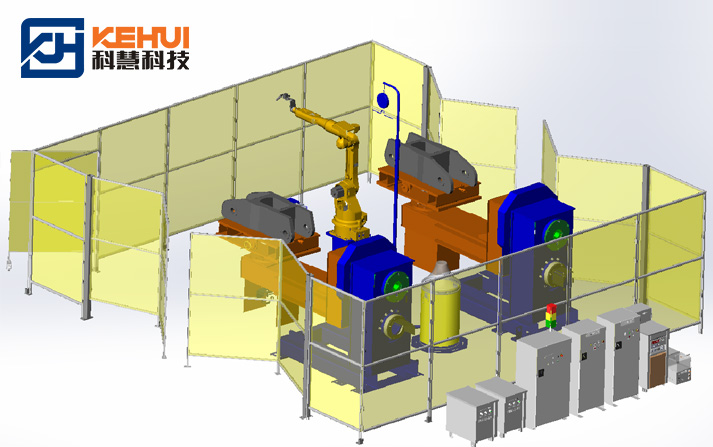

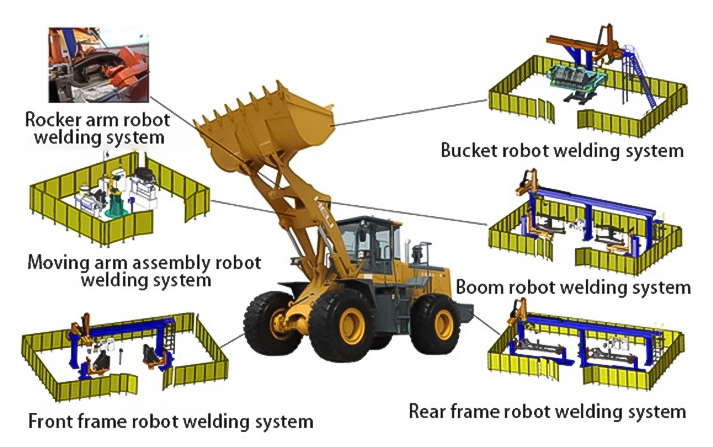

Automotive Body Welding Automated Manufacturing Solutions  Bulldozer beam and bucket robot welding cobot assembly line

Bulldozer beam and bucket robot welding cobot assembly line  Suspension parts of semi-trailer fully automated production line

Suspension parts of semi-trailer fully automated production line  Aluminum alloy container side box robot automated welding manufacturing line automation

Aluminum alloy container side box robot automated welding manufacturing line automation